Kidde Clean Agent Systems

The AFP Group is an authorized distributor of Kidde Clean Agent Systems.

Content on this page is taken with permission from the KiddeFenwal website.

ADS with Kidde Fluoro-K Fire Suppression Agent

Fire Suppression System

Ideal for Long Distances and Complex Piping Networks

The Kidde Advanced Delivery System (ADS) type Clean Agent Suppression System using Fluoro-K improves the performance of 360 psi (25 bar) or 500 psi (35 bar) systems by using a Nitrogen driver to propel the agent through the piping network. This innovation provides better coverage, greater nozzle heights, smaller diameter pipe and longer pipe runs than a standard clean agent suppression system.

ADS System with Fluoro-K Benefits:

- Provides economical protection of multiple enclosures when used with directional valves

- If space is not restricted, placement in or near hazard area allows for smallest possible pipe diameter to be used, resulting in installation cost savings

- Increased flow rates allow for better coverage of larger hazard areas

ADS System with Fluoro-K Features:

- Cylinders can be located up to 200 feet from hazard area

- Nozzle can be placed at a height of up to 18’6″

- Nozzle coverage area of up to 42’6″ x 42’6″

Natura Inert Gas System

Flexible. Efficient. Sustainable.

The Kidde Fire Systems Natura Inert Gas System provides flexibility with your choice of four agents, efficient installation and overall lower total cost of ownership driven by reduced material, installation and labor costs, as well as a more economical refill cost after a discharge.

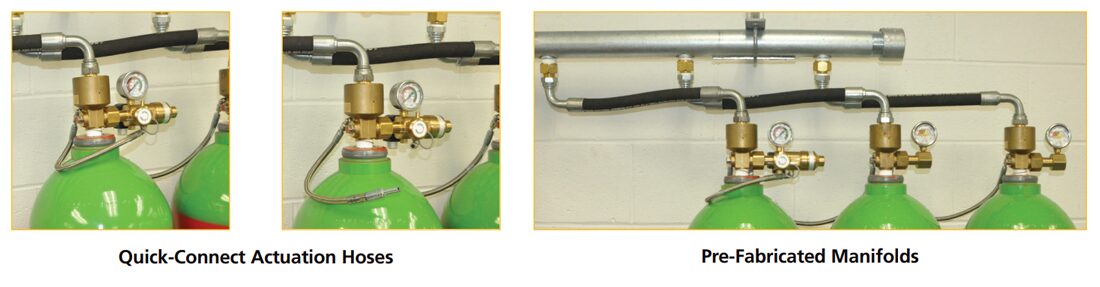

Compared with other high pressure inert gas systems, our series 400 valve regulates flow and pressure to allow the use of Schedule 40 piping for many applications. Installation time and labor costs are further reduced with the use of pre-fabricated manifolds, quick-connect actuation hoses and electrical connectors.

System Benefits

FLEXIBILITY

- Choice of four NFPA and ISO approved agents to suit re-charge conditions and customer specifications

- Wide flexibility when selecting storage area as cylinders can be stored hundreds of feet from hazard

- Argon may be used for application-specific Class D materials such as titanium dust, magnesium, etc.

- Suitable for low-temperature applications

- Suitable for rooms that are hard to seal and open spaces such as museums and labs

LOWER MATERIAL COSTS

- Pressure and flow regulating valve allows for Sch. 40 pipe

- Actuation up to 60 cylinders accomplished with a single release unit mounted on the primary cylinder so there is no need for separate pilot cylinders

- Selector valves protect multiple hazards with a single cylinder bank, reducing overall system cost

LOWER INSTALLATION, LABOR, AND REFILL COSTS

- Several sizes of pre-fabricated manifolds with pre-installed check valves ready for discharge hose connections

- Fast & easy installation using quick-connect actuation hoses and electrical connections

- Economical agent refill cost after a discharge

ECS-500™ Clean Agent Suppression System

with Kidde Fire Systems Fluoro-K

The ECS-500 clean agent fire suppression system introduces improved system design flexibility with reduced installation and material costs.

The ECS-500 type Clean Agent Suppression Systems provide superior performance compared to 360 psi/25 bar systems. The higher storage pressure of 500 psi (35 bar) enables improvement of agent travel distance for applications where ADS™ performance levels are not required. Now you have the flexibility of a mid-tier solution to meet application size, design requirements and the client’s budget.

Benefits:

- New 1,100 lb. cylinder reduces cylinder quantities and installation time required while providing enough agent to cover up to a 27,000 cubic feet area with a single cylinder

- Increased system pressure allows for longer pipe runs and use of smaller pipe diameters

- Provides flexibility to remotely locate cylinder storage area more than twice the distance from the hazard area when compared to 360 psi/25 bar systems

- Can be used with existing 4.0 HASP Key flow calculation software

High Pressure CO2 (HP CO2) Fire System

The Kidde High Pressure Carbon Dioxide (HP CO2) System is ideal for industrial processes where flammable materials and vapors present a potential fire hazard.

The Kidde HP CO2 System utilizes highly sophisticated electric and/or pneumatic detection units which sense fire at its inception. It is designed specifically for each hazard and operated automatically, to ensure immediate detection and rapid suppression.

The Kidde HP CO2 Fire Suppression System is an engineered system available in three application configurations: total flooding (for unoccupied areas), local application or hand-hose line. Gaseous carbon dioxide rapidly suppresses fire by a combination of cooling and oxygen displacement. Discharge duration and agent flow rates are customized for the individual application.

FEATURES

- Proven quality and reliability with the Kidde brand.

- Tested and approved all of Kidde’s various detection and control options.

- An inexpensive and easy-to-access agent when refill is necessary.

- Wide ranges of proven safe, hazard protection.

TECHNICAL SPECIFICATIONS

- Reduces the oxygen content of the atmosphere to a point where combustion becomes impossible

- Hardware to accommodate any application and system type

- Offered in 25 lbs. to 100 lbs. cylinders

- Hose reel line systems

- Directional valve system options

- Lockout valves and lockout circuits

LISTING APPROVALS

- FM Approved

- UL Listed

- USCG Approved

- MEA Approved

Cardox Low-Pressure CO2 Fire System

The CARDOX Low-Pressure Carbon Dioxide (LP CO2) System is a proven solution when used to protect areas that require multiple suppression cycles, expansion capabilities, numerous hazards or more than 5000 lbs of CO2.

O2 is an odorless, colorless, inert gas that extinguishes fire primarily by diluting the oxygen that supports combustion. It is applied by either the “total flooding” or the “local application” method. CO2 is not recommended for normally occupied spaces, except when other means of fire protection are not effective.

Total flooding delivers CO2 into an enclosure until the fire is extinguished. For open hazards, the CO2 local application method blankets the hazard extinguishing the flames and cooling the hazard. In “total flooding”, the enclosure of the hazard protected is flooded to a proper concentration. In “local application”, CO2 is directly applied in the proper amount at the rate required to cover the protected hazard.

We have the expertise and product line to protect a full range of hazards with vertical and horizontal storage tanks ranging from 2¾ ton to 60 ton and are available in 120, 220, 380, 460 and 575 volts, 50/60Hz, single and three-phase variants. Optional CSA and PED approved systems are also available.

FEATURES

- Fast-acting, within seconds CO2 penetrates the entire hazard area to smother the fire.

- Less expensive to replenish than other agents.

- Does not require hydrostatic testing.

- Leaves no residue, eliminating the need for time-consuming and costly clean-up

- Effective on a wide range of flammable and combustible materials in both surface and deep-seated fires.

- Allows for multiple hazard protection from a common piping system.

- Addresses hazards with partial enclosures or unenclosed equipment

- Compensates for continuous air handling process

- Suitable for extreme temperatures

- Horizontal or Vertical Installation

- Allows for multiple and extended discharges

- Variety of standard/stock refrigeration packages available

LISTING APPROVALS

- FM Approved

WHDR Wet Chemical Kitchen System

The Kidde Fire Systems WHDR Wet Chemical Fire Suppression Kitchen System offers 24-hour automatic or manual protection for commercial cooking areas; ducts, plenums, hoods and cooking surfaces.

The Kidde Fire Systems WHDR Wet Chemical Kitchen System is a cost-effective, pre-engineered fire protection solution designed for a quick and easy installation. The system offers unmatched coverage, with fewer discharge nozzles and flow points than the competition, meaning reduced installation time and cost. It exceeds stringent UL 300 standard and complies with NFPA Standards 96 and 17A.

The WHDR system is specifically designed for the challenging demands posed by cooking applications. By offering one of the most flexible system configurations in the industry, Kidde provides efficient, economical protection for all types of cooking facilities and design layouts. Our customized approach allows you to specify the type of detection, control and cylinder sizes to fit your application.

LISTING APPROVALS

- UL 300 Listed

- ULC/ORD-C1254.6 Listed

- NYC COA

- American Bureau of Shipping

- ISO 15371

- APC provides fastest flame knockdown and best securement

- Four cylinder sizes available

- Meets strict UL 300 fire test criteria

LISTING APPROVALS

- UL 300 Listed

- ULC/ORD-C1254.6 Listed

- NYC COA

- American Bureau of Shipping

- ISO 15371

IND Dry Chemical Fire System

The Kidde Fire Systems IND Dry Chemical System provides 24-hour fire protection for a wide variety of industrial processes, equipment, machinery and paint spray booth applications.

The IND Dry Chemical system offers the choice of two dry chemical agents effective on Class A, B and C fires. It is available in two basic configurations: as a local application system or a total flood system. A local application system is designed to protect a specific piece of equipment, while a total flood system is recommended for protection of enclosed rooms or spaces. In addition to the configurations, the IND System also offers options for detection and control to create a system that will be ideal for your application.

FEATURES

- Easy to design

- Safe and reliable fire protection

- Flexible installation parameters

- Pre-Engineered design offers economical installation

TECHNICAL SPECIFICATIONS

- Two types of dry chemical: Multi-purpose and Standard

- Six cylinders sizes

- Proven controls and detection

- Variety of actuation options

LISTING APPROVALS

- UL Listed

- ULC Listed

- FM Approved

- NYC FD Approved (MEA)

detect-a-fire

The World Standard in Mechanical Heat Detectors

DETECT-A-FIRE detectors are the “heart” of many fire protection systems. The highly reliable D-A-F has been the standard for over 75 years. The D-A-F is used for signaling overheat or fire conditions. In the vast majority of applications, the D-A-F provides the initial heat sensing that is used to activate suppression systems using clean agent, CO2, inert gases, wet or dry chemicals, or water.

D-A-F detectors are widely accepted, because they are designed with rate compensation. This provides a unique advantage over both fixed temperature and rate-of-rise types of detectors because the D-A-F detector accurately senses the surrounding air temperature regardless of the fire growth rate. At the pre-determined set point, the system is activated. Fixed temperature detectors must be completely heated to alarm temperature and therefore a lag in response time may occur with a fast rate fire. Rate-of-rise devices, on the other hand, are triggered by the rate of increase in ambient temperature and are subject to false alarms caused by harmless, transient thermal gradients such as the rush of warm air from process ovens.

FEATURES

- Repeatable – self-restoring, nothing to replace, testable

- Versatile – various temperature settings available

- Durable – long lasting stainless steel shell

- Economical – wide spacings reduce installation costs

- Factory set

- Internal contact area hermetically sealed in stainless steel shell

- ROHS Compliant

APPLICATIONS

- Protection of schools, factories, offices, libraries, or other non-residential buildings

- Power generation

- Gas station islands

- Paint spray booths

- Range hoods

- Engine compartments

Contact Us

Contact Form

Hours

Mon - Fri, 8:30 - 5:00

24-hr Emergency Service

Location

6746 Akron Road

Lockport, NY 14094